Key Accident Prevention Techniques When Working with Electricity

Working with electricity may have become so customary to your business’s operations that accident prevention techniques aren’t really given much thought. Electrical shock, electrocution, fires, and explosions are all risks workers are exposed to on a daily basis. The Occupational Safety and Health Administration (OSHA) recognizes these hazards and has designed standards to prevent potential injuries. Are you familiar with the most up-to-date standards? Make sure that you and your team are well-versed in what to do to prevent accidents and injuries.

Insulation

Shocks, fires, and short circuits could all be prevented by using insulators such as glass, mica, rubber, or plastic to coat metals and other conductors to reduce the flow of electrical current. Effective insulation must be suitable for the specific voltage, and other environmental factors such as moisture, oil, gasoline, corrosive fumes or other substances that may result in faulty insulation must be taken into account.

Guarding Electric Equipment

Guarding means to enclose electric equipment so that people don’t accidentally come into contact with it. For effective guarding, ensure that only authorized employees qualified to work directly with electrical equipment have access to it.

Grounding

OSHA recommends using guarding as a secondary protective measure to substantially reduce the risk of electrical hazards. Grounding an electrical tool or system involves intentionally create a low-resistance path that connects to the earth which prevents the buildup of voltages that could cause an electrical accident.

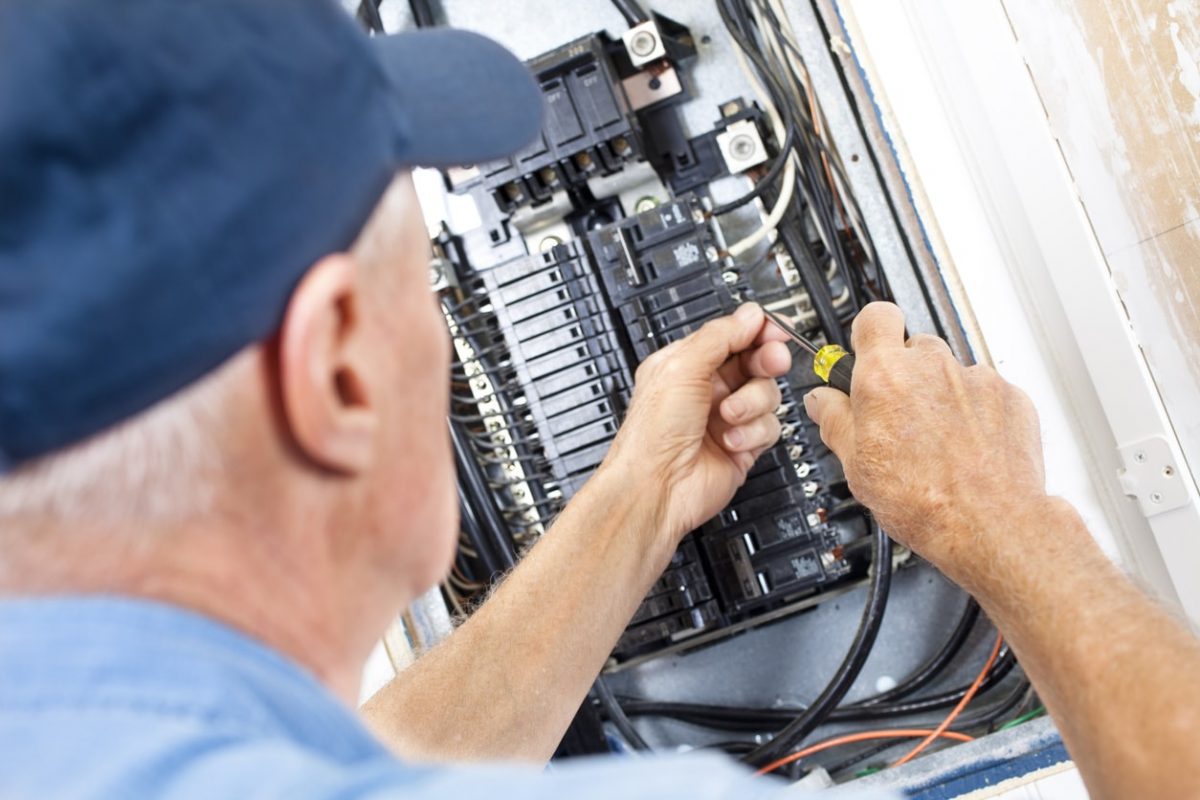

Circuit Protection

Circuit protection devices limit or stop the flow of current automatically in the event of a ground fault, overload, or short circuit in the wiring system. Fuses, circuit breakers, ground-fault circuit interrupters, and arc-fault circuit interrupters are all circuit protection devices.

Other Quick Tips

Here are some additional tips to help keep electrical injuries from happening in the workplace:

- Always identify electrical hazards before starting work, and label them clearly so anybody passing by can easily identify them.

- Keep equipment away from energy sources and only use equipment specifically made for the job at hand.

- Use non-conductive ladders to avoid being shocked at significant heights. This can also prevent falls.

- Be cautious of outlets that are hot to the touch. This may indicate bad wiring and could result in an electrical fire.

- Never nail or staple extension cords into place. Only ever use electrical tape for this purpose. Damaged cords can lead to electrical fires and shocks. Thoroughly inspect all electrical cords before use and never use a cord that shows signs of damage.

- Always wear proper protective clothing and use insulated tools when around electrical hazards.

Neglecting electrical hazards can lead to serious bodily injuries. By implementing accident prevention techniques when dealing with tools or areas that have potential electrical hazards, you ensure that you create a safe environment for employees. In addition to doing everything you can to create a safe working environment, you should also protect yourself and your employees with a comprehensive insurance program. Whether you run an electrical business or operate in another sector that requires electrical work, make sure that you have workers’ compensation and any other insurance policy that is relevant to your risk profile. Not sure what that is? Contact us today; we’re happy to help.

About Daniels Insurance, Inc.

At Daniels Insurance, Inc., we have a unique understanding of the risks that people like you face on a regular basis. With the backing of our comprehensive coverages and our dedication to customer service and quick claims resolution, your business will be fully protected. For more information, contact us today at (855) 565-7616.